Guest writers: Darren King, WSP group director of rail planning and operations, and William Barter, an independent rail operations and planning consultant.

In ‘Rail’, there is a simple eco-system that exists, which should always be respected by the industry’s design engineers. The operator may be the immediate customer; but the passenger, freight user and, in a broader sense, the region in which the railway exists, are the ultimate customers. This means that an engineering design, and its final construction, is only as good as the operation it enables; understanding what that operation is trying to achieve is vital for the engineer to design infrastructure that supports it.

To be effective, consultants need to look through the lens of the ultimate customer, first to those who are going to have to plan, operate and maintain a train service after completion of the project, then to the objectives that the train service aims to meet. In other words, they need to make sure they are helping their clients to put the passenger or freight user first.

Design consultants such as WSP take a user-focused approach. This means providing a service specification that meets the strategic objectives of the project and informs how the railway needs to be operated. In effect, this sets the basis for final engineering elements that will deliver an operation that meets the end users’ needs.

Often, the operator’s detailed requirements are only understood late on in the design process or, even worse, after construction has started. This inevitably leads to costly alterations or a compromised operational performance which fails to deliver. To some extent, this will always be the case, as analysis can only be based on the inputs available at the time; the project development process simply must allow for it, and recognize that there is uncertainty in analysis of potential operations at an early stage, just as there is in engineering estimates.

Good engineering may not be the same as a good project. Operators may well appreciate the need to maximise construction windows and engineers should understand the need to run a railway around construction windows. But ‘efficient’ construction that ultimately hampers the end product, such as sacrificing operating functionality for the convenience of the construction programme, is actually not efficient at all.

Integrated, iterative and collaborative

Building a new railway, or enhancing an existing one, is not a linear, Gantt-chart activity; instead it requires an integrated and iterative process to assure the final design. Time has proven that this is the only approach that enables the right level of evidence to be provided to support a business case that meets all its objectives. Moreover, an integrated design process can identify and highlight the big risks and opportunities in time for action to be taken.

Adopting such a joined-up design process can only occur within a mature and collaborative environment – one which encourages a multi-disciplinary approach. It requires the railway to be seen by all stakeholders as a system which clearly defines and sets rail systems engineering requirements and capabilities – one that ultimately meets the needs of the freight or passenger customer.

It is only once the way a rail system needs to operate to meet its desired performance is fully understood that the type of technology that is needed to achieve that end goal can be defined. This is not always what happens – too often the opposite is true.

Putting the process into practice

‘Operability’ is the term now used to describe the ability of the rail system to provide a train service that meets its objectives. Broadly, this means meeting the sponsor’s specification for journey times, service frequencies and stopping patterns, all while meeting performance targets and without incurring excessive operating costs.

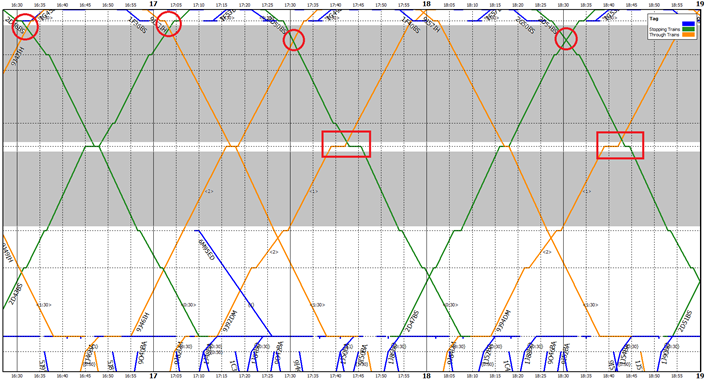

Analysis of the potential operability of a project reflects its specific objectives, for example to increase capacity, reduce costs or encourage modal shift. This analysis has to be staged, just as in engineering design. Fully formed train service plans – plans that match the development of the physical infrastructure as the design moves from broad concept, through alignment and track layout, to comprehensive design complete with signalling schemes and other supporting systems such as electrification and tunnel ventilation – do not ‘just happen’!

The stages of operability analysis can be characterised as:

- Initial appraisal based on known precedents;

- Theoretical calculation of headways and trains per hour (tph);

- Building a timetable with the associated resources plan for fleet and crew;

- Performance modelling;

- Actual operation.

Operability analysis starts where overriding objective meets binding constraint. This overriding objective might be a tph target, and to efficiently enable it, other areas may have to work ‘inefficiently’, perhaps at less than their full theoretical capability if considered in isolation.

An example may be a station design that is theoretically generous with the track layout and provision of platforms in comparison with the number of trains set to arrive there. But this over-compensation may well allow maximum utilisation of the terminus. This could be even more important if, as an example, the station is subject to minimum infrastructure provision as it is in a space-constrained urban setting.

This is just one example of why each component of a network must be considered part of the system as a whole.

Changing requirements

There also needs to be an iterative process between engineering disciplines and operator as the design matures.

Findings from each stage can lead to revisions of the design, and this must be respected beyond the usual ‘operators changing their minds again’ response. For instance, timetabling analysis may show a need for a major station design to incorporate two platforms in each direction, so as to accommodate the number of trains expected, rather than the one platform in one direction originally scoped. Without an engineering team (in the widest sense) willing and able to recognise this requirement, and the operational issues that led to it, the end user would have had to compromise on stopping pattern, service frequency or journey time.

Similarly, the general requirement for a three-minute planning headway on the approach to another major station seemed reasonable. However, timetabling showed that, as trains would present from three independent routes, each planned around their own constraints, there was a high likelihood that they would coincide, needing a lower headway to avoid extending journey times waiting for a path.

In new circumstances beyond the conventional railway, where the learning curve can be steep, it is important that each engineering discipline interacts with every other, as well as with the operator, to deal effectively with the inevitable surprises.

These surprises can arise from seemingly innocuous changes. On a recent project, the distance between tunnel ventilation shafts had to be reconsidered when a ‘one-train-between-shafts’ rule was added to the constraints of the original design. In this instance, the solution was to align signalling sections with ventilation shafts. This introduced longer block sections in the tunnels than in the open air, increasing the technical headway, but not beyond acceptable limits – so long as trains are running at speed. In this instance, the final shaft-to-portal section of the tunnel became the ‘binding constraint’ on a headway, as the speed of the train reduces to zero when it reaches the station.

Incidentally, although initial requirements for rescue and evacuation might set a maximum shaft spacing, operations may suggest reducing this spacing to achieve acceptable headways. Ideally, shafts will be located evenly in terms of transit time, not just distance – a revelation the Victorians discovered when locating block posts for Absolute Block signalling.

The same station-approach project threw up another challenge when a late aspiration emerged that, when trains brake in tunnels, they should rely on regeneration-only braking, which is gentler and generates less ambient heat than the friction braking that was originally intended. Designers had to account for longer transit times and headway, caused by trains having to brake earlier to reduce their speed.

Any mitigations introduced at a late stage of design should result in permanent way and signalling layouts which place the minimum possible constraint on train speed, so as not to limit the speed of arriving trains any more than the simple need to stop at the platform.

On railways, whether they are conventional or high-speed, regional or inter-city, every discipline has an input in achieving an operable network that meets its objectives, even those not normally considered as part of the traditional railway infrastructure, such as tunnel ventilation.

Railway design calls for a multi-disciplinary approach, which needs to be set in a mature and collaborative environment as all components of the system are developed together.

Five guiding principles

Broad principles to help engineers interact with their customers during project development:

Understand the strategic and commercial objectives from the outset of the project. What is the ultimate goal? Is it capacity, journey time, connectivity? Establishing this forms the basis for making informed trade-offs as the engineering design progresses and finds problems. Otherwise the temptation is to “spoil the ship for a bucket of tar” when running into trouble, such as descoping the physical infrastructure for the sake of short-term benefits to the construction programme, perhaps by reducing the number of platforms to achieve a one-stage construction.

Operability analysis and development of an illustrative operational plan and timetable is not a rubber stamp! Let the analysis feedback into development of the infrastructure. The surprise should not be that the analysis prompts changes to the original infrastructure specification, but how often it doesn’t!

Operability analysis can increase and reduce costs. For instance, capability of fringe areas of the network may determine how well the core works. It may be more cost-effective to invest in the fringes to ease the task of the core, rather than over-specify the core to mask inflexibility elsewhere.

Operability analysis needs to consider operational performance. But success involves multiple systems working together – not just the broad alignment with gradients and speed limits, but the track layout, the signalling scheme that can be designed onto it, and operational rules and procedures. The data to support this emerges relatively late in the design, and detailed, data-hungry models are pointless until the design can provide a usable level of input detail. Designers need to develop wide-area network simulators that work from minimum relevant data input and so can be applied early in the design development.

Needs will change over time. A rail project’s lifetime can be measured in decades, if not a century or more as it meets new demands. The task is not simply to pour concrete, based on a single solution for the problems posed by one specification, and move on, but to build in choices that our successors can exploit as they see fit in decades to come.